Mechanical Piping, Process Equipment & Skid Fabrication/Installation

At STRUCTURAL, we understand that industrial operations depend on the performance and reliability of complex mechanical systems. From process piping to structural steel and critical process equipment, our team delivers the expertise and resources needed to support safe, efficient, and uninterrupted production.

We provide comprehensive mechanical services, both in-shop and on-site, for the installation, repair, and modification of essential industrial systems.

Certified welders use the following welding processes:

Let STRUCTURAL be your trusted partner for mechanical solutions that meet the highest standards of quality, safety, and reliability.

Specialty Services

Our services include, but are not limited to the following:

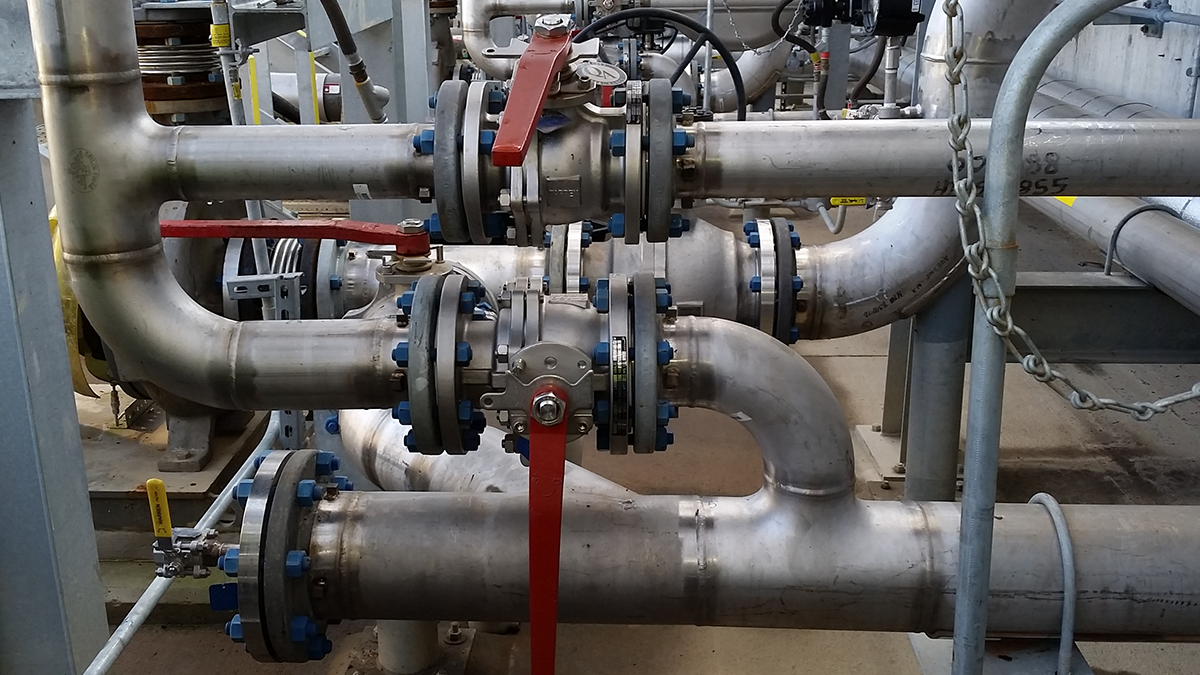

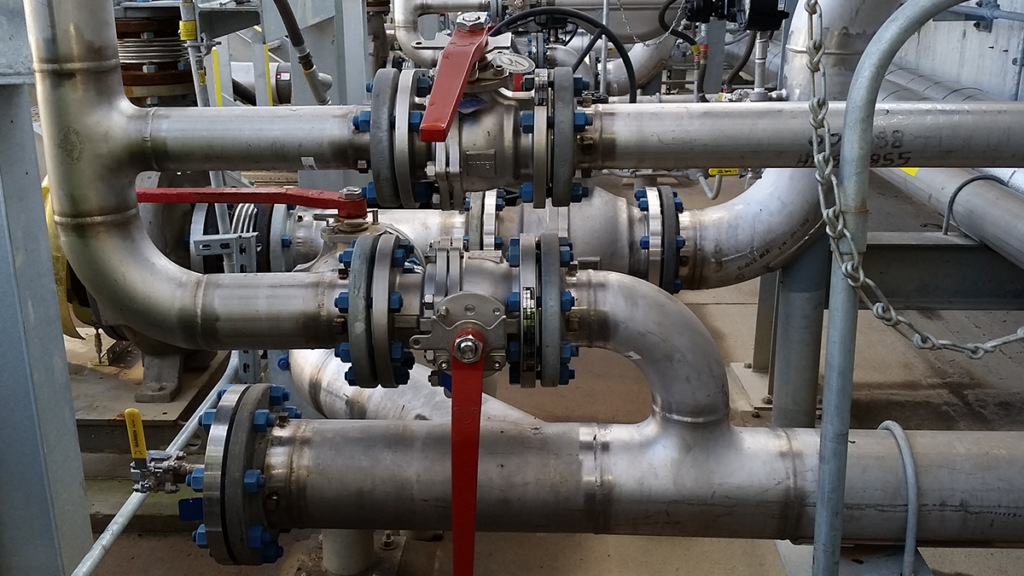

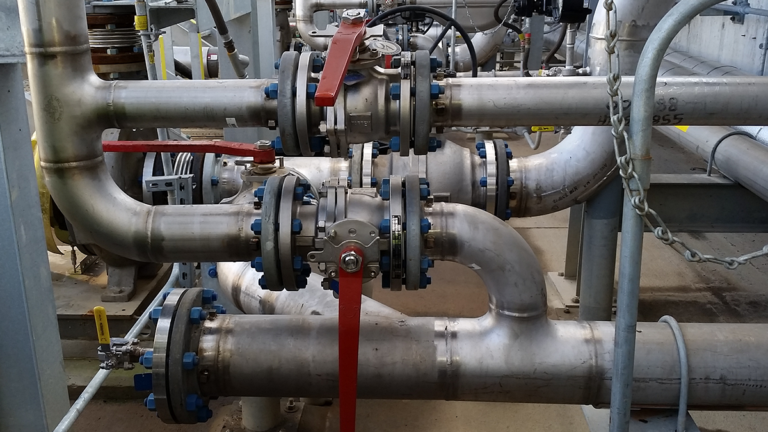

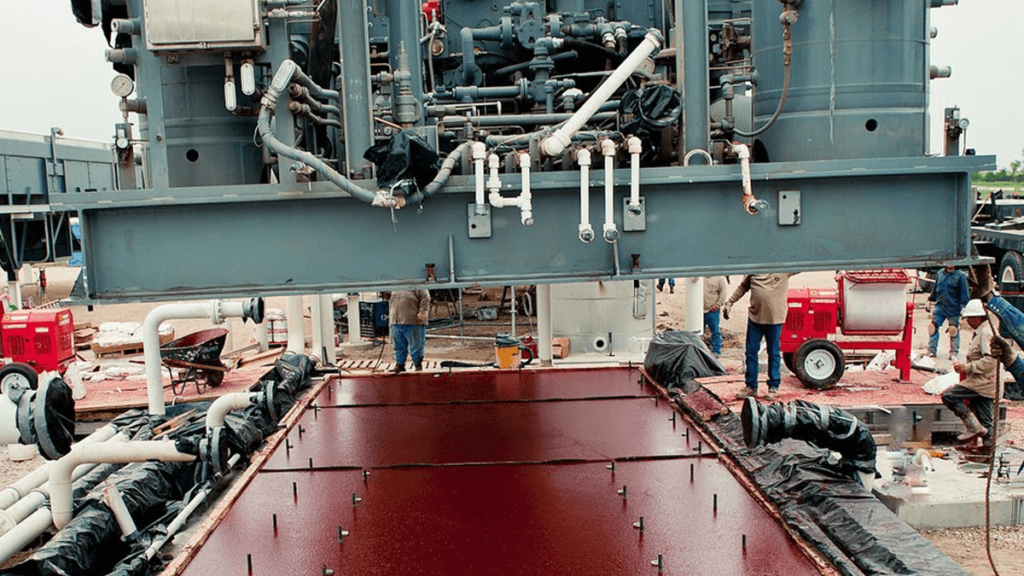

Skid Fabrication

STRUCTURAL offers turnkey skid fabrication and field installation services tailored to client-provided engineered drawings. Our in-house fabrication team builds fully integrated skids—including frames, process piping, valves, insulation, and select electrical and instrumentation components—with precision and compliance to API and ASME standards.

By combining expert shop fabrication with robust QA/QC protocols and seasoned field crews, we deliver single-source solutions that minimize lead times, reduce project complexity, and ensure performance from shop to site.

Our Commitment to Safety & Preplanning

STRUCTURAL’s project management and field personnel carefully plan each project. Our crews work closely with customers to address all areas of concern during project pre-planning, including safety, constructability, budgeting, scheduling, and phasing as it relates to optimizing efficiency and potential disruption to facility operations.

Our crews have the flexibility and manpower to match work schedules to project needs. We can complete projects under the tightest schedules or adjust and phase work to create work schedules that minimize disruption. Regardless of the conditions, our focus is on quality, on-time performance with the highest standard of safety for both our workforce and our customers.